Airium® flooring systems

Main uses

Airium® in floors can be used in different ways and can be adapted to fit local norms and systems:

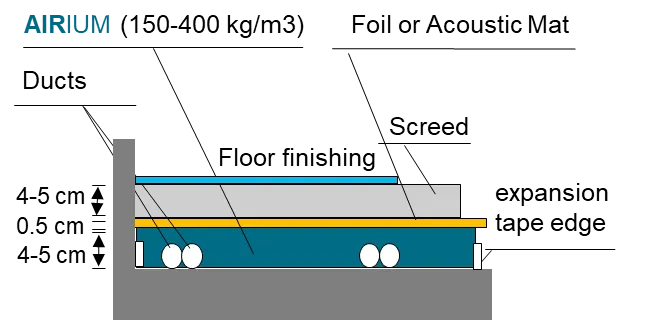

- as a sub-screed layer in ground floors or intermediary floors (150 to 400 kgs/m3) for a great level, easily covered ducts and pipes and a contribution to thermal and acoustic performance

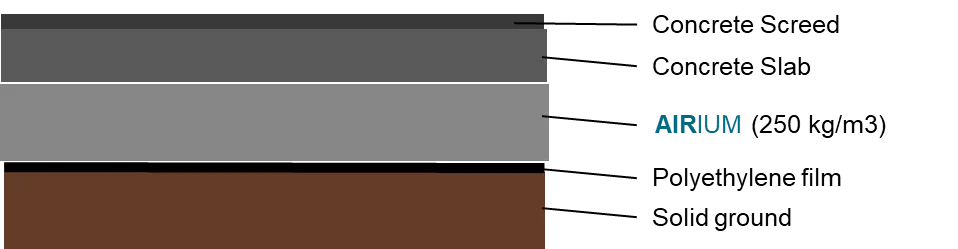

- as a sub-slab insulating material replacing both insulation and lightweight concrete with no compaction step (250 kg/m3)

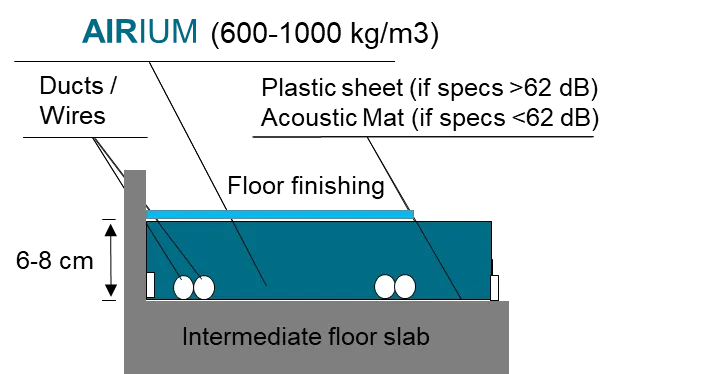

- as an all-in-one easy to level lightweight screed (600 to 1000 kg/m3)

Main benefits

|

Image

|

For developers and investors, Airium® flooring offers durable insulation, a perfect levelling solution, stability over time, and contributes to lower the overall weight per square meter. |

|

Image

|

For contractors and applicators, Airium® simplifies life on site: no storage, no cutting and placing of boards, no EPS beads flying on site, no crane required to lift materials to higher floors as Airium® is pumped from the ground, no need to get on one’s knees to apply the material. Airium® is also very fast to apply (e.g. ~200 m2 in one hour for a 5 cm thickness) |

|

Image

|

For the planet, Airium® is mineral and easy to recycle along with the slab with no separation phase. By lowering the densities and the deadload of buildings in different flooring systems, Airium® also contributes to lowering the CO2 intensity of flooring systems |

How it works

Airium® can be brought to site and pumped to your floor by different methods: with an integrated and automatic Airium® truck, with a pump producing the mineral foam on site and fed with a premix in bags or in a silo, or with a pump receiving a specially made slurry from one of our ready-mix trucks. Holcim works hand in hand with application companies to deliver the best end-result. Airium® typically sets in about 6 hours and can be walked upon after 24 hours (depending on local conditions). It requires a drying time of about 1 day per centimetre before being covered with a screed or a final layer.

Airium Flooring system explained, Poland

Typical systems

Use case 1:

Airium® used as a sub-screed simplifies work and logistics on site, provides a better levelling than fossil fuel-based alternatives and contributes to thermal and acoustic comfort. Below is an example of such a system. The exact system must be adapted to local norms and needs of each country.

Airium Flooring project example, Poland - Mikolaj Kutyra

Airium Flooring project example, Austria - Michael Grabner

Use case 2:

Airium® below the slab replaces both the insulation layer and any additional backfilling or levelling layers. It also eliminates the need for the time-consuming compaction step. Below is an example of such a system. The exact system must be adapted to local norms and needs of each country.

Use case 3:

Airium® as a screed may substantially lighten the load and the weight of a building (circa. 4 times lighter than a traditional screed). Below is an example of a system. The exact system must be adapted to local norms and needs of each country.